Polyvinyl Chloride (PVC) Plastisol Coating, Liquid Plastisol

PECOAT® PVC Plastisol for PVC Plastisol Coating

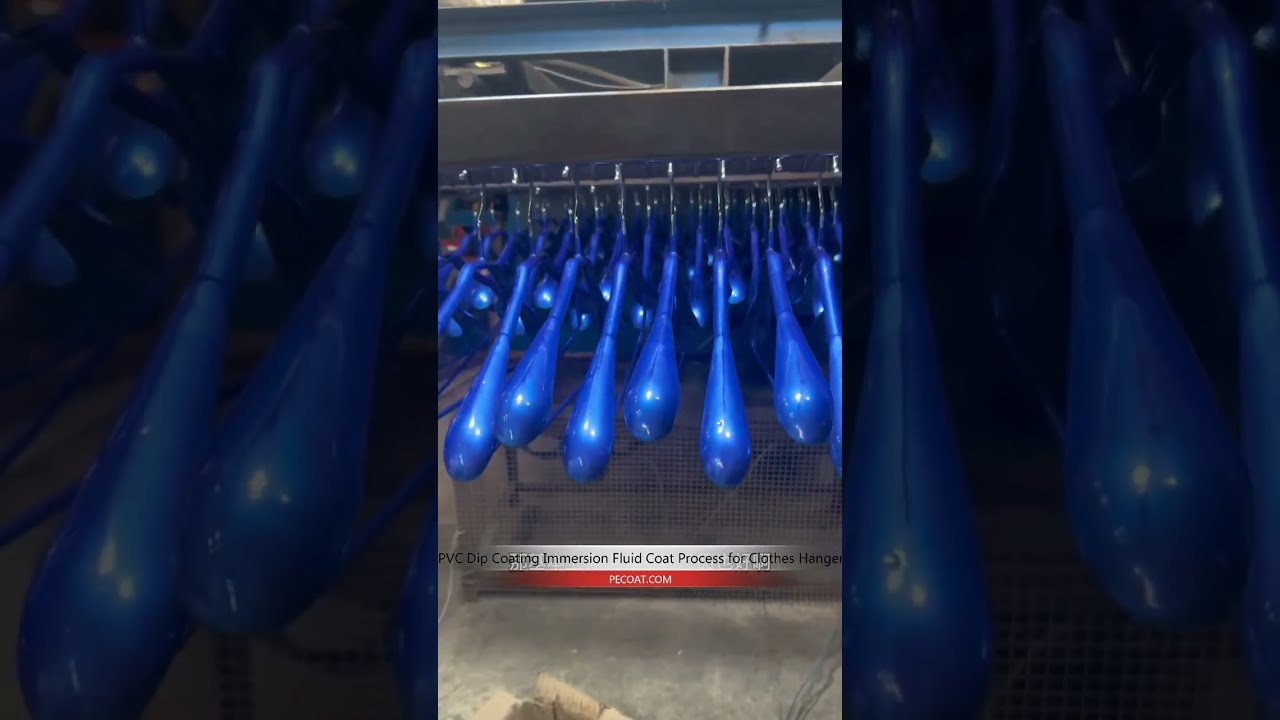

PECOAT® PVC Plastisol is made from polyvinyl chloride (PVC) as the main raw material, mixed with various additives, and refined through multiple processes. The products coated with PVC plastisol coating are colorful and beautiful with porcelain-like gloss. The coating has good wear resistance, tensile strength, heat resistance, and high insulation,and does not shrink or crack in winter or summer, and it has a good touch, long service life, and safe and reliable, providing particularly good protective and decorative effects. PVC plastisol is widely used in dip moulding process and dip coating process.

Color Matching

The typical approach to color matching involves three methods.

Surface Matching

Four types of surface effect are for option. Customization is also available according to customers’ sample.

Given the many advantages of liquid dip PVC plastisol coating, its usage is widespread across various industries. The coating thickness ranges from approximately 0.1 to 15mm.

- Hardware Tool Handles: Wrenches, pipe pliers, needle-nose pliers, diagonal pliers, wire cutters, gardening tools, and various types of scissors.

- Fitness Equipment: Handles like dumbbells, pull-up bars, treadmill accessories, and handles for various fitness equipment.

- Electromechanical Products: Power tool accessories, fan accessories, automotive interior decorations, and electrical insulation components.

- Architectural Hardware: Valve handles, door locks, handles, security doors, security windows, stairs, and furniture.

- Daily Used Hardware: Clothes hangers, chains, trash bins, vehicle locks, and various types of chains.

- Plastic Sleeves: Medical-grade plastic sleeves, long plastic sleeves, and colored sleeves.

Dip Molding

Dip Coating

- Pretreatment: The workpiece takes enough pretreatment, removing oil and rust.

- Prepare PVC plastisol: Pour the liquid PVC plastisol into the tank three hours in advance, let it stand still and remove the surface bubbles before use.

- Preheat: Preheat the workpiece to 230-250℃ for 2-3 minutes.

- Dip: Immerse the preheated workpiece into the liquid plastisol.

- Observe the thickness and flow of the coating to ensure the proper state.

- Post-heat: Put the workpiece into the curing oven to heat at 200℃ for 2-3 minutes.

- Cooling: Take it out for cooling.

PECOAT® PVC Plastisol Coating is Packaged in High-quality Iron Drums.

- Iron drums have excellent mechanical properties, high pressure resistance, strong ductility, and are not easily damaged. They provide reliable safety assurance for products during long-distance transportation and are convenient for storage, transportation, loading, unloading, and use.

- Iron drums have excellent comprehensive protection performance. The water vapor permeability of steel is very low, completely opaque, and can effectively avoid the harmful effects of ultraviolet rays. Therefore, iron drums can maintain the quality of goods for a long time. Moreover, iron drums are reusable and recyclable.

250KG/Drum, 4 Drums/Pallet

Depending on different market, certain products necessitate a strong adhesion for the coating. However, PVC coatings inherently lack adhesion properties. In light of this, PECOAT® has developed specialized adhesive primer to enhance the adhesive capabilities of PVC coatings. Simply brush or spray them evenly onto the metal surface to be coated prior to the dipping process. The products’ substrate treated with adhesive primer exhibit exceptional adhesion to the plastic coatings, and it is difficult to peeling.

- Working temperature: 230 – 270℃

- Packing: 20kg/Plastic jugs

- Color: Transparent and colorless

- Specific gravity: 0.92-0.93 g/cm3

- Storage: 1 years

- Use method: Brush or spray

- What product do you coat?

- What color you need?

- What surface effect you need?

- Do you have any specific requirementsfor hardness? If so, please tell us Shore C hardness value. In the absence of special requests, we usually use Shore C 60°

- Do you have special requirements for other properties of the coating? For example, anti-UV, anti-static, high insulation and so on.

- (1) Oven temperature, that is, the preheating temperature of the workpiece.

- (2) Temperature of the plastisol.

When you become proficient in operating the equipment, it is not difficult to control the appropriate coating thickness according to the product requirements.

PVC Plastisol Material Safety Data Sheet

Dip Molding Technology and Its Application in Automobile

An Overview of Dip Coating and Dip Molding

Manufacturing Process of Plastic Coating

PVC plastisol coating for ultrasonic cleaning basket

Plastisol PVC Liquid : flexible durable material in various industries

Plastisol Dip Coating :The Durable Solution for Coating Needs

Choosing the Best PVC Dip Coating Supplier: Key Considerations

Adhesion Primer improve the adhesion bonding of PVC coatings

Reference values of viscosity for common liquids