LDPE Powder Coating Thermoplastic Powder

Introduction of LDPE powder coating

LDPE powder coating is a type of coating that is made from low density polyethylene (LDPE) resin. This type of coating is commonly used in a variety of industries, including appliance, automotive, aerospace, and construction.

Powder coating is a process in which a dry powder is applied to a surface using an electrostatic charge or fluidized bed. The powder is then heated to a high temperature, causing it to melt and form a smooth, even coating. LDPE powder coating is a variation of this process that uses LDPE resin as the coating material.

LDPE powder coating is the largest and most widely used thermoplastic powder coating. The excellent resin provides the basis for high-gloss coatings.

Advantages

The coating has the following advantages:

- excellent water resistance, acid and alkali resistance, chemical resistance, and water absorption rate below 0.001%;

- good thermal insulation and electrical insulation, no electric corrosion;

- excellent tensile strength, flexibility, and impact resistance;

- good low-temperature resistance, no cracking at -40℃ for more than 400 hours, suitable for use in cold environments in the north;

- low raw material cost and non-toxic.

This type of powder coating gives the coating excellent leveling, softness, and wax-like feel. When the coating of low-density thermoplastic powder coating comes into contact with certain solvents or detergents, it will quickly break due to stress cracking.

Usually, other resins are used to modify polyethylene resin to greatly improve the mechanical properties of polyethylene powder coating, improve its adhesion to the substrate, and promote the development of this type of coating, greatly expanding its application fields.

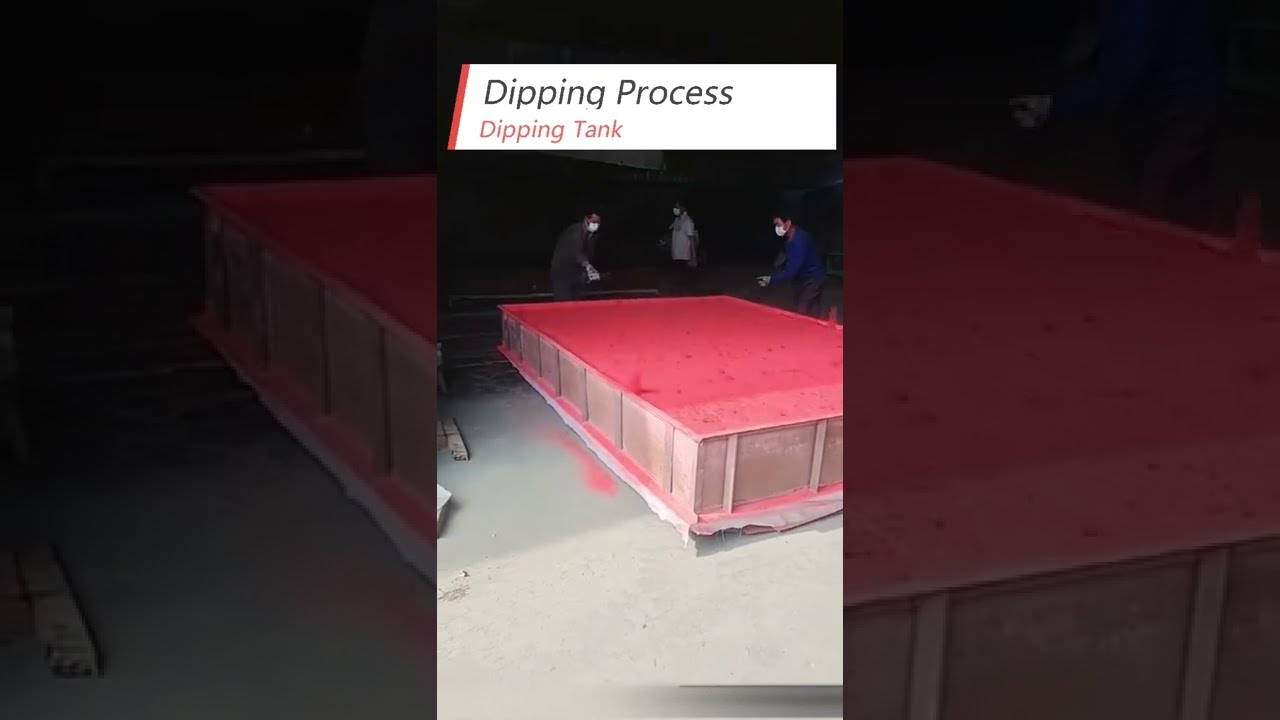

Thermoplastic LDPE powder coating can be applied by fluidized bed immersion coating or electrostatic powder coating, generally using the former.

However, this type of powder coating also has some shortcomings, specifically in:

a) poor hardness, wear resistance, and mechanical strength of the coating;

b) poor adhesion of the coating, generally requiring strict sandblasting, shot blasting, surface treatment, or primer coating of the substrate;

c) poor weather resistance, prone to stress cracking after exposure to ultraviolet radiation.

Use Method for LDPE Powder Coating

Leave a Reply