Thermoplastic PE Polyethylene Powder Coating

PECOAT® PE Powder for Polyethylene Powder Coating

PECOAT® PE Polyethylene Powder is a thermoplastic powder coatings modified with low density polyethylene (LDPE) resin as based material, formulated with various functional additives to provide excellent performance. It has excellent adhesion, anti-corrosion properties, good chemical stability, electrical insulation and low temperature resistance of polyethylene itself. Typically, they are widely used to coat household and industrial metal wire products. This is because they provide a smooth and attractive surface coating that is hard enough to withstand severe wear and tear.

Main Features

Some Popular Colors

About Colors of PE Polyethylene Powder Coating

We can offer any bespoke colour to match your needs. Color Reference

Use Market

PECOAT® thermoplastic polyethylene powder coatings are designed for toughness, durable and anti-corrosion performance, without a primer. The material is environmentally friendly, no VOC, no hazardous fumes during using. Its single layer thermoplastic coatings provide long term saving on maintenance, material costs and operating cost , and are used by a wide range of industries.

- Good chemical resistance

- Enhanced temperature resistance

- Excellent mechanical resistance

- Food contact

- Environmentally friendly

- Smooth finish

- Good surface hardness

- Long term durability

- Superior corrosion resistance

- High impact and abrasion resistance

- UV stability

- Weather resistance (climate, humidity, temperature variation)

- Protection of galvanized substrates

- Environmentally friendly

- Good resistance to temperature

- Good UV stability, no yellowing of white products

- Flexible coating,no risk of cracking, chipping or flaking

- Environmentally friendly

- Good metal coverage, including for sharp edges and welds

- Smooth finish

- Good surface hardness

- Excellent chemical and corrosion resistance

- High impact and abrasion resistance

- UV stability

- Protection of galvanized substrates

- Soft touch

- Environmentally friendly (no VOC, halogen free, BPA free)

- Acid resistance

- Excellent adhesion while flexible

- Excellent insulation properties

- Superior corrosion resistance, oil resistance

- High impact and abrasion resistance

- UV stability

- High adhesion and flexibility

- Electrical insulation

PECOAT® Fire Extinguisher Cylinder Coating is designed especially to coat the interiors of water and foam-filled fire extinguishers, it is applied by rotational lining to metal cylinders to give a protective coating with excellent resistance to aqueous environments, including the foaming agent A.F.F.F. and is also resistant to up to 30% Antifreeze (ethylene glycol).

Power cable conduit is a composite material made of steel pipe as the base, coated with polyethylene powder coating on the inner and outer walls through a special process and cured at high temperature. Due to its good anti-static and anti-external signal interference capabilities, it is used in power protection projects in various environments.

PECOAT® PP506 polyethylene powder is designed for coating cable conduit (power conduit ). It is a solvent-free, 100% solid powder coating developed with high-performance polyethylene as the base resin and combined with various specialty resins. This product has extremely high adhesion, excellent aging resistance, weather resistance, good flowability, and features such as solvent-free, non-polluting, environmentally friendly, and energy-saving.

Read more >>

Packing

25Kg/Bag

PECOAT® thermoplastic polyethylene powder coating is firstly packaged in a plastic bag to prevent the product from being contaminated and damp, as well as to avoid powder leakage. Then, packed with a woven bag to maintain their integrity and prevent the inner plastic bag from being damaged by sharp objects. Finally palletize all bags and wraped with thick protective film to fasten the cargo.

Now ready for delivery!

Request A Sample

Different substrate condition has different requirement for coating property, such as adhesion, flowing ability, temperature endurance, etc, these information is the basis of our sample design.

To maximize the chances of success of sample testing, and being responsible for both parties, kindly please supply the following information. Thank you so much for your serious treatment and cooperation.

FAQ

- What product do you coat? It is better to send us a picture.

- What is the substrate material, galvanized or non-galvanized?

- For sample testing, 1-25kg/color, send by air.

- For formal order, 1000kg/color, send by sea.

- Mechanical removal: Use tools such as sandpaper, wire brushes, or abrasive wheels to scrape or grind off the coating.

- Heating: Apply heat to the coating using a heat gun or other heating device to facilitate its removal.

- Chemical strippers: Use appropriate chemical strippers specifically designed for powder coatings, but follow safety precautions when using them. This is a strong acid or a strong base.

- Sandblasting: This method can remove the coating but need sandblasting machine.

- Scraping: Use a sharp tool to carefully scrape off the coating.

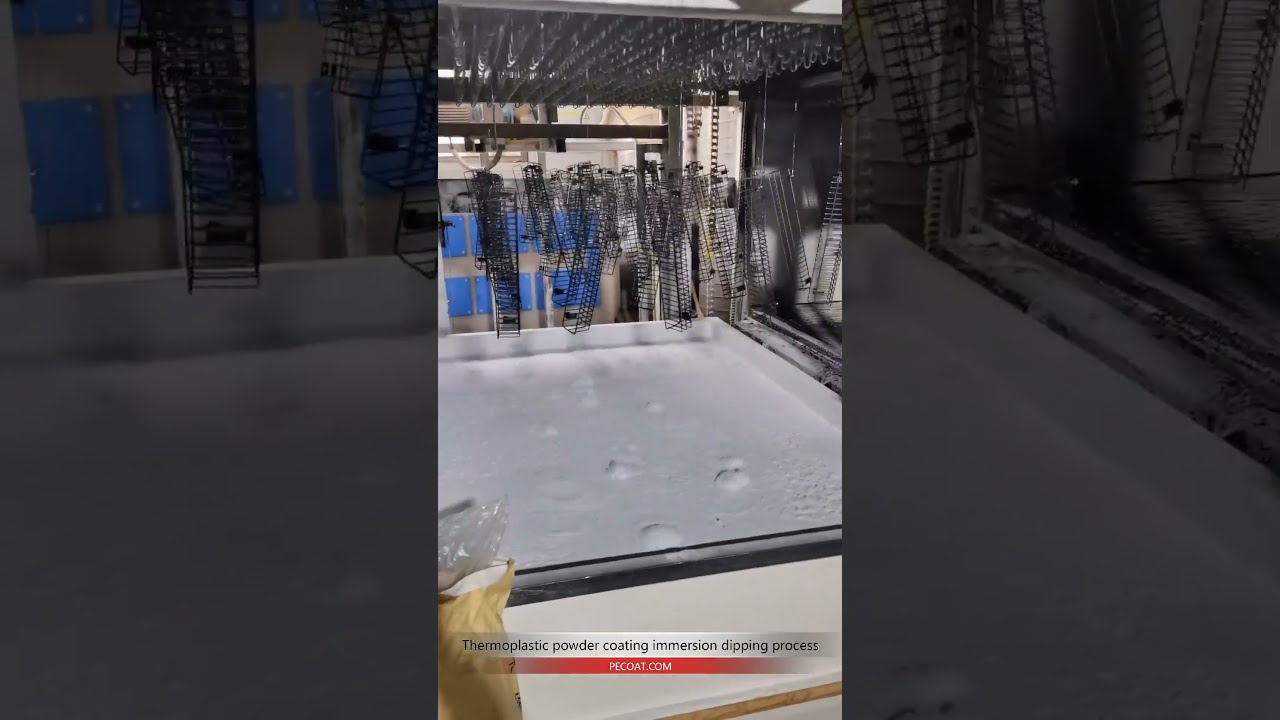

Use Method

The preheated workpiece is completely immersed into fluidized bed. The powder melts on contact with the workpiece and the workpiece is then lifted out of the fluidized bed. The workpiece is then cooled to leave a high-quality coating.

The preheated workpiece is completely immersed into fluidized bed. The powder melts on contact with the workpiece and the workpiece is then lifted out of the fluidized bed. The workpiece is then cooled to leave a high-quality coating.

- Pre-treatment: Oil and rust removed by chemical method or sandblasting.

- Workpiece Preheat: 250-320℃ [ adjusted according to the workpiece].

- Fluidized Bed Dip: 4-8 seconds [adjusted according to the workpiece].

- Post-heat(optional): 180-250℃, 5 minutes [ Beneficial to obtain a better surface ].

- Cooling: Air-cooled or naturally cooled.

Our electrostatic series of cryogenically-ground powders are fine enough to be electrostatically charged and sprayed onto grounded metal workpieces. The metal workpieces are then placed in an industrial oven and heated until the powder melts. The items are then cooled to leave a high-quality coating.

Our electrostatic series of cryogenically-ground powders are fine enough to be electrostatically charged and sprayed onto grounded metal workpieces. The metal workpieces are then placed in an industrial oven and heated until the powder melts. The items are then cooled to leave a high-quality coating.  The workpiece to be coated will be preheated at an appropriate temperature, depending on its properties, thickness, and heat capacity. Uncharged powder is blown onto the hot metal, where it melts and forms a coating. The item is then allowed to cool to leave a high-quality coating.

The workpiece to be coated will be preheated at an appropriate temperature, depending on its properties, thickness, and heat capacity. Uncharged powder is blown onto the hot metal, where it melts and forms a coating. The item is then allowed to cool to leave a high-quality coating.  The object that requires coating, typically a bottle, pipe or cylinder, is heated up to the required temperature. Fluidized bed powder is then injected into the object. The object is then immediately spun and tumbled to give a complete and consistent coating inside the bottle. Any unused powder is then tipped out of the object.

The object that requires coating, typically a bottle, pipe or cylinder, is heated up to the required temperature. Fluidized bed powder is then injected into the object. The object is then immediately spun and tumbled to give a complete and consistent coating inside the bottle. Any unused powder is then tipped out of the object.  The thermoplastic powder is dispersed through the gun nozzle and blown inside the flame created around the nozzle, the powder melts on transit from the gun to the workpiece surface and instantly turns solid coating when comes in contact with the workpiece.

The thermoplastic powder is dispersed through the gun nozzle and blown inside the flame created around the nozzle, the powder melts on transit from the gun to the workpiece surface and instantly turns solid coating when comes in contact with the workpiece. Project Example

Use Videos

PE Powder Coating VS PVC Powder Coating

| PE Powder Coating | PVC Powder Coating | |

|---|---|---|

| Curing Temperature | 180-220℃ | 230°C-250°C (more energy consumption) |

| Environment Friendly | Yes | No (harmful gas HCL emission during use) |

| Coating Thickness | 200-2000μm (wide range thickness, easily controlled) | 800-1000μm (narrow range thickness, usual thin coating) |

| Powder Consumption ( at same thickness) | Less | More |

| Surface | Smooth | A bit rough,not very smooth |

| Adhesion Ability | Excellent | Not have, special primer is required |

| Price | High | Cheaper |