Category: Thermoplastic Powder Paint

Thermoplastic powder paint is a type of coating process that involves applying a dry powder paints of thermoplastic material onto a substrate, usually a metal surface. The powder is heated until it melts and forms a continuous, protective coating. This coating process can be done using several techniques, including electrostatic spraying and fluidized bed dipping.

Thermoplastic powder paints offers several advantages over traditional liquid coatings, including:

- Durability: Thermoplastic paints are highly durable and resistant to impact, abrasion, and chemicals, making them ideal for use in harsh environments.

- Ease of application: Thermoplastic powder paints can be applied more easily and uniformly than liquid coatings, which can help to reduce material waste and improve efficiency.

- Cost-effectiveness: Because thermoplastic paints can be applied more efficiently, they can often be less expensive than liquid coatings in the long run.

- Environmental friendliness: Thermoplastic paints are free of volatile organic compounds (VOCs), which can make them a more environmentally friendly alternative to liquid coatings.

Common types of thermoplastic powder paint used for coating include polyethylene, polypropylene, nylon, and PVC. Each type of powder has its unique properties and is suitable for different applications, depending on the specific requirements of the substrate being coated.

Buy PECOAT® PE Thermoplastic Polyethylene Powder Paint

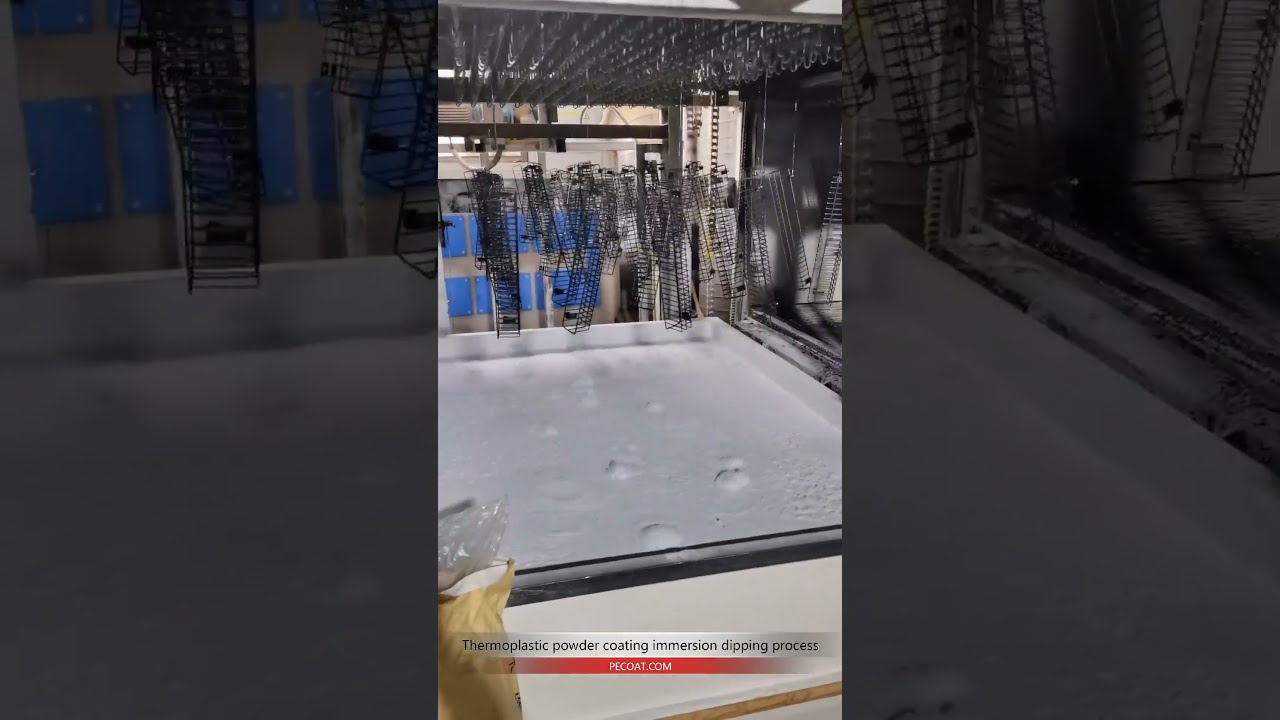

Fluidized Bed Dipping Process

PVC Powder Coating Suppliers In China

General Steps to find PVC Powder Coating Suppliers from China I do not have access to real-time information or specific recommendations for suppliers of PVC powder coating. However, I can suggest a few ways you can find PVC powder coating supplier: Online search: You can use search engines like Google to search for PVC powder coating supplier. Try using relevant keywords like “PVC powder coating supplier” or “PVC powder coating manufacturers” to get a list of suppliers. You can alsoRead More …

Thermoplastic dip coating for complex-shaped parts

What is thermoplastic dip coating? Thermoplastic dip coating is a process where a heated thermoplastic material is melted and then applied to a substrate through dipping. The substrate, which is usually made of metal, is preheated to a specific temperature and then dipped into a container of molten thermoplastic material. The substrate is then withdrawn and allowed to cool, which causes the thermoplastic material to solidify and adhere to the surface of the substrate. This process is commonly used forRead More …

Thermoplastic polyurethane (TPU) Introduction

Thermoplastic polyurethane (TPU) is a type of polymer that belongs to the family of thermoplastic elastomers. It is a versatile material that is known for its high durability, flexibility, and resistance to oils, greases, and abrasion. TPU is produced by combining a diisocyanate (a type of organic compound) with a polyol (a type of alcohol). The resulting material can be melted and re-melted repeatedly, making it ideal for use in injection molding and extrusion processes. TPU is commonly used inRead More …

Thermoplastic Coating for Metal

What is thermoplastic coating for metal? Thermoplastic coating for metal – Thermoplastic coatings are an excellent choice for protecting metal surfaces from corrosion, wear, and abrasion. These coatings are applied to metal surfaces in a molten state and then allowed to cool and solidify, creating a durable and long-lasting protective layer. There are many different types of thermoplastic coatings available for metal, including: Polyethylene: This type of coating is commonly used for pipelines and other applications where resistance to abrasionRead More …

Thermoplastic Coating Process

Thermoplastic Coating Process Introduction The thermoplastic coating process involves the application of a thermoplastic material to a substrate, typically a metal, plastic, or concrete surface. The coating is heated until it melts into a liquid state and is then applied to the substrate using a variety of methods, such as spraying, dipping, or brushing. The substrate is usually cleaned and prepared before applying the thermoplastic coating. This involves removing any debris or contaminants, such as rust or grease, that mayRead More …

Polyethylene plastic is polyethylene as main component

The main component of polyethylene plastic is polyethylene. Its raw material ethylene mainly comes from petroleum cracking and cracking, which belongs to petrochemical products. Polyethylene (PE) is one of the five major synthetic resins, and it is the variety with the largest production capacity and the largest import volume among synthetic resins in my country. Polyethylene is mainly divided into three categories: linear low-density polyethylene (LLDPE), low-density polyethylene (LDPE), and high-density polyethylene (HDPE). Application Plastic wrap, vest-style plastic bags, plasticRead More …

What is thermoplastics?

Thermoplastics are a class of plastics that are plastic at a certain temperature, solidify after cooling, and can repeat this process. The molecular structure is characterized by a linear polymer compound, which generally does not have active groups, and does not undergo linear intermolecular crosslinking when heated. Waste products can be reprocessed into new products after recycling. The main varieties are polyolefins (vinyls, olefins, styrenes, acrylates, fluorine-containing olefins, etc.), cellulose, polyether polyesters and Aromatic heterocyclic polymers, etc. Definition Thermoplastics areRead More …

Fusion Bonded Epoxy FBE Powder Coat for 3LPE Pipeline

Fusion Bonded Epoxy (FBE) powder coating is commonly used as a corrosion protection coating for 3LPE pipelines. It is applied to the external surface of the pipeline to provide a durable and protective barrier against corrosion. FBE powder coating is typically applied using electrostatic spray or fluidized bed methods. The powder is heated and melted onto the surface of the pipeline, forming a continuous and uniform coating. Once cooled, the FBE coating provides excellent adhesion and resistance to chemicals, moisture,Read More …

Thermoplastic vs Thermoset

Thermoplastic vs Thermoset Thermoplastic refers to the property that a substance can flow and deform when heated, and can maintain a certain shape after cooling. Most linear polymers exhibit thermoplasticity and are easily processed by extrusion, injection or blow molding. Thermosetting refers to the property that it cannot be softened and molded repeatedly when heated, and it cannot be dissolved in solvents. Bulk polymers have this property. Thermosetting is a chemical change. After being heated, the structure has changed andRead More …

Nylon Powder Coating for Undergarment Accessories and Underwear Bra Tips

PECOAT® Undergarment Accessories special nylon powder a thermoplastic polyamide 11 powder coating, it is made of high-performance nylon through special physical processes. The powder is in regular spherical shape. It is an excellent environmentally friendly, non-toxic and harmless powder coating suitable for surface coating of small parts. It has excellent physical and chemical properties, and its wear resistance, flexibility, and low-temperature impact resistance are all very good, which can well meet the high-end application requirements of lingerie accessories. It isRead More …