Category: Thermoplastic Powder Paint

Thermoplastic powder paint is a type of coating process that involves applying a dry powder paints of thermoplastic material onto a substrate, usually a metal surface. The powder is heated until it melts and forms a continuous, protective coating. This coating process can be done using several techniques, including electrostatic spraying and fluidized bed dipping.

Thermoplastic powder paints offers several advantages over traditional liquid coatings, including:

- Durability: Thermoplastic paints are highly durable and resistant to impact, abrasion, and chemicals, making them ideal for use in harsh environments.

- Ease of application: Thermoplastic powder paints can be applied more easily and uniformly than liquid coatings, which can help to reduce material waste and improve efficiency.

- Cost-effectiveness: Because thermoplastic paints can be applied more efficiently, they can often be less expensive than liquid coatings in the long run.

- Environmental friendliness: Thermoplastic paints are free of volatile organic compounds (VOCs), which can make them a more environmentally friendly alternative to liquid coatings.

Common types of thermoplastic powder paint used for coating include polyethylene, polypropylene, nylon, and PVC. Each type of powder has its unique properties and is suitable for different applications, depending on the specific requirements of the substrate being coated.

Buy PECOAT® PE Thermoplastic Polyethylene Powder Paint

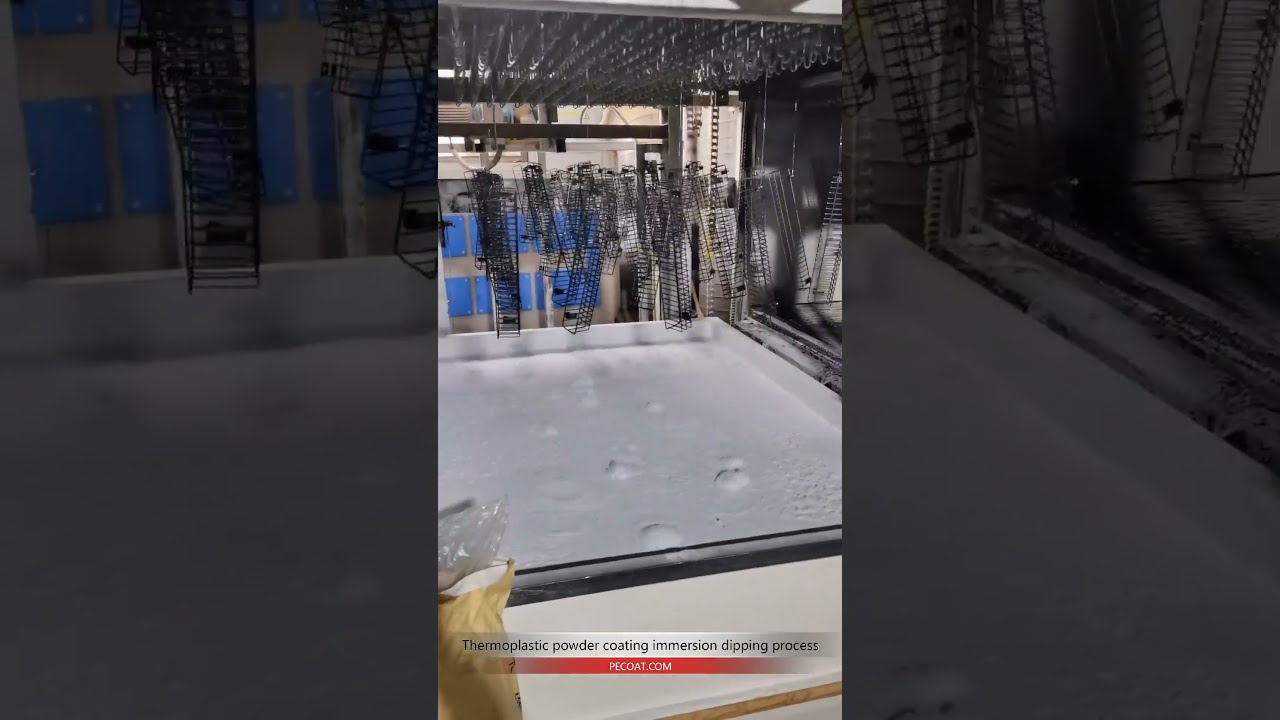

Fluidized Bed Dipping Process

Find Polyethylene Powder Suppliers in China

To find polyethylene powder suppliers in China, you can follow these steps: 1. Online Research Start by conducting online research using search engines, business directories, and B2B platforms. Look for keywords like “polyethylene powder suppliers in China” or “polyethylene powder manufacturers in China.” This will provide you with a list of potential suppliers. 2. Trade Shows and Exhibitions Attend trade shows and exhibitions related to the plastics industry in China. These events often attract suppliers and manufacturers showcasing their products.Read More …

Thermoplastic Powder for Dipping Purposes

Introduction of thermoplastic powder for dipping purposes Thermoplastic powder for dipping purposes is a type of powder coating material that is used to provide a protective and decorative coating to various objects. The coating is applied through a dipping process, where the object is immersed in a container filled with the thermoplastic powder. The powder particles adhere to the surface of the object, forming a uniform and continuous coating. The thermoplastic powder is typically made from a polymer resin, whichRead More …

What is the difference between thermoplastics and thermosets

Thermoplastics and thermosets are two types of polymers that have distinct properties and behaviors. The main difference between the two lies in their response to heat and their ability to be reshaped. In this article, we will explore the differences between thermoplastics and thermosets in detail. Thermoplastics Thermoplastics are polymers that can be melted and reshaped multiple times without undergoing any significant chemical change. They have a linear or branched structure, and their polymer chains are held together by weakRead More …

Common 6 Types of Polyethylene

Several Types of Polyethylene Polyethylene is a versatile polymer that is widely used in various industries. There are several types of polyethylene, each with its own unique properties and applications. Here are some of the most common types: 1. Low-Density Polyethylene (LDPE): LDPE is a flexible and transparent polymer with a low melting point. It is commonly used in packaging films, plastic bags, polyethylene coating and squeeze bottles. LDPE is known for its excellent chemical resistance and good electrical insulationRead More …

Popular 5 Uses of Polyethylene

Polyethylene – A Versatile Polymer in Multiple Industries Polyethylene, a versatile polymer, finds numerous applications across various industries due to its low cost, durability, and resistance to chemicals and moisture. Here are five common uses of polyethylene: 1. Packaging Polyethylene is extensively used in the packaging industry. It is employed to manufacture plastic bags, shrink wrap, polyethylene coating and stretch film. Polyethylene bags are widely used for grocery shopping, food storage, and waste disposal. Shrink wrap is used to packageRead More …

PP or PE Which is Food-grade

PP and PE are both food-grade materials. PP has a higher melting point and can be used to make soy milk bottles, juice bottles, microwave meal boxes, etc. PE has a wider range of applications and is commonly used in the production of fiber products such as clothing and blankets, medical equipment, automobiles, bicycles, parts, conveyance pipes, chemical containers, as well as food and drug packaging. The main component of PE is polyethylene, which is recognized as the best materialRead More …

Plastic Coating For Metal

Plastic coating for metal process is to apply a layer of plastic on the surface of metal parts, which allows them to retain the original characteristics of metal while also providing certain properties of plastic, such as corrosion resistance, wear resistance, electrical insulation, and self-lubrication. This process is of great significance in expanding the application range of products and enhancing their economic value. Methods for plastic coating for metal There are many methods for plastic coating, including flame spraying, fluidized bedRead More …

Is polypropylene toxic when heated ?

Polypropylene, also known as PP, is a thermoplastic resin and a high molecular polymer with good molding properties, high flexibility, and high temperature resistance. It is widely used in food packaging, milk bottles, PP plastic cups and other daily necessities as food-grade plastic, as well as in household appliances, automotive parts and other heavy industrial products. However, it is not toxic when heated. Heating above 100℃: Pure polypropylene is non-toxic At room temperature and normal pressure, polypropylene is an odorless,Read More …

Physical Modification of Polypropylene

Adding organic or inorganic additives to the PP (polypropylene) matrix during the mixing and compounding process to obtain high-performance PP composite materials. The main methods include filling modification and blending modification. Filling modification In the PP molding process, fillers such as silicates, calcium carbonate, silica, cellulose, and glass fibers are added to the polymer to improve heat resistance, reduce costs, increase rigidity, and reduce molding shrinkage of PP. However, the impact strength and elongation of PP will decrease. Glass fiber,Read More …

Nylon 11 Powder Coating

Introduction Nylon 11 powder coating has excellent wear resistance, seawater corrosion resistance, and noise reduction advantages. Polyamide resin is generally called nylon, which is a white or slightly yellow powder. It is a widely used thermoplastic powder coating. Common varieties include nylon 1010, nylon 6, nylon 66, nylon 11, nylon 12, copolymer nylon, terpolymer nylon, and low melting point nylon. They can be used alone or mixed with fillers, lubricants, and other additives. Nylon 11 is a resin produced byRead More …