Category: Plastisol Dipping Technology

Plastisol dipping technology is a process used in the manufacturing of various products, including clothing, toys, and industrial components. It involves dipping a substrate, such as fabric or metal, into a liquid polymer called plastisol, which is then cured to form a solid coating.

Plastisol is a suspension of PVC particles in a liquid plasticizer. It is a versatile material that can be formulated to have different properties, such as flexibility, durability, and resistance to chemicals and UV light. Plastisol is also easy to work with, as it can be molded, printed, and coated onto various substrates.

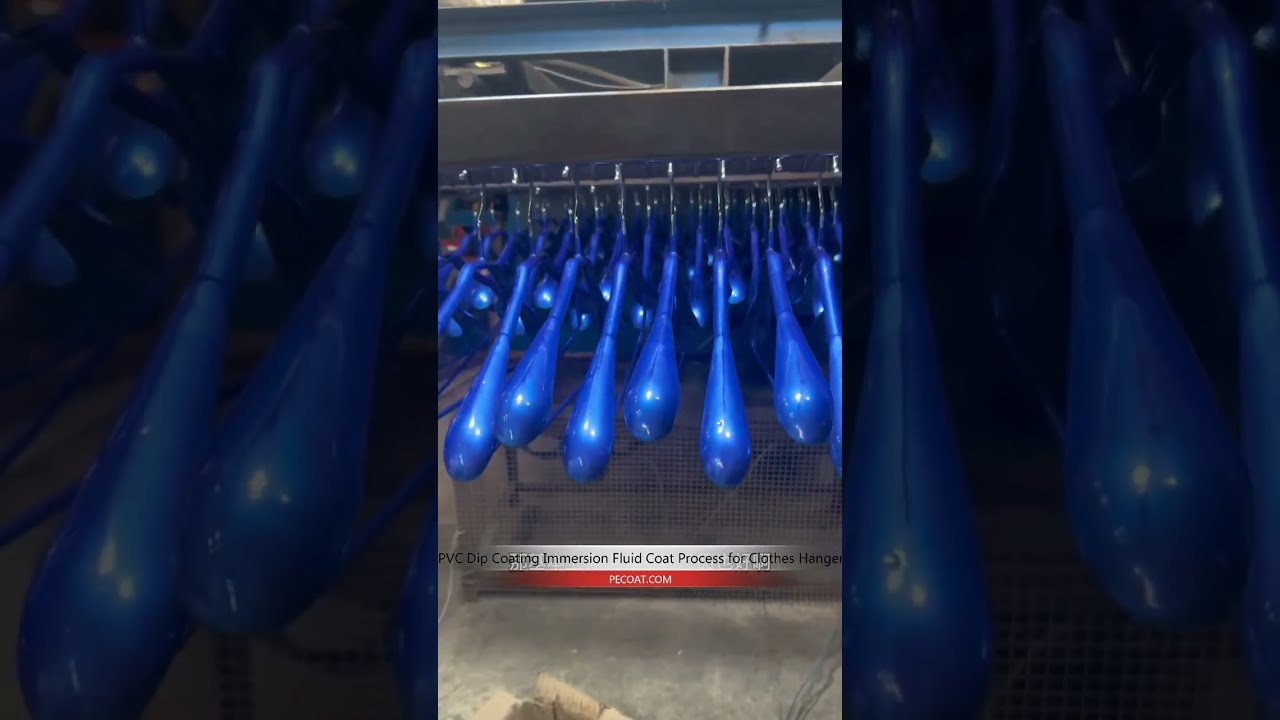

The plastisol dipping process starts with the preparation of the substrate, which is cleaned and pre-treated to ensure good adhesion and surface finish. The substrate is then dipped into a tank of plastisol, which is heated to a temperature of around 180-200°C. The heat causes the plastisol to fuse and crosslink, forming a solid coating on the substrate. The thickness of the coating can be controlled by adjusting the dipping time and the viscosity of the plastisol.

After the dipping process, the coated substrate is cured in an oven or a conveyorized dryer, which heats the plastisol to a higher temperature for a specific time. This step ensures that the plastisol is fully cured and has the desired properties, such as hardness, flexibility, and color stability.

Plastisol dipping technology has many advantages over other coating and printing methods. It can produce a uniform and consistent coating on complex shapes and surfaces, such as 3D objects and irregularly shaped parts. It can also create a variety of textures and finishes, such as glossy, matte, and textured. Plastisol coatings are also resistant to abrasion, impact, and weathering, making them suitable for outdoor and industrial applications.

In the textile industry, plastisol dipping is commonly used for printing designs and logos on t-shirts, sweatshirts, and other garments. The plastisol ink is applied to the fabric by screen printing or transfer printing, and then cured to form a durable and vibrant print. Plastisol printing is preferred over other methods, such as water-based and discharge printing, because it can produce opaque and bright colors on dark fabrics, and does not require pre-treatment or post-curing.

In the toy industry, plastisol dipping is used to create soft and flexible toys, such as rubber ducks, balls, and figurines. The plastisol is molded into the desired shape and then cured to form a solid and durable toy. Plastisol toys are safe for children to play with, as they do not contain harmful chemicals, such as phthalates and lead, which are found in some other types of plastics.

In the automotive and industrial industries, plastisol dipping is used to coat metal parts, such as handles, knobs, and levers, to improve their grip, durability, and appearance. Plastisol coatings can also provide insulation and corrosion resistance, making them suitable for electrical and marine applications.

Overall, plastisol dipping technology is a versatile and cost-effective process that can be used to create a wide range of products with different properties and applications. It is a popular choice for manufacturers who require high-quality and durable coatings on various substrates.

PVC Plastisol Material Safety Data Sheet

Introduction of PVC Plastisol PVC plastisol is a common plastic coating widely used in fields such as wire, cable, and construction materials. However, due to its chemical composition and potential risks during use, it is crucial to use and store PVC plastisol correctly. This document will provide a detailed introduction to the safety techniques of PVC plastisol, aiming to assist users in applying the product in a reasonable and safe manner. Characteristics Composition: PVC plastisol is mainly composed of polyvinylRead More …

- 1

- 2