Plastic Coating For Metal

Plastic coating for metal process is to apply a layer of plastic on the surface of metal parts, which allows them to retain the original characteristics of metal while also providing certain properties of plastic, such as corrosion resistance, wear resistance, electrical insulation, and self-lubrication. This process is of great significance in expanding the application range of products and enhancing their economic value.

Methods for plastic coating for metal

There are many methods for plastic coating, including flame spraying, fluidized bed spraying, powder electrostatic spraying, hot melt coating, and suspension coating. There are also many types of plastics that can be used for coating, with PVC, PE, and PA being the most commonly used. The plastic used for coating must be in powder form, with a fineness of 80-120 mesh.

After coating, it is best to quickly cool the workpiece by immersing it in cold water. Rapid cooling can reduce the crystallinity of the plastic coating, increase water content, improve the toughness and surface brightness of the coating, increase adhesion, and overcome coating detachment caused by internal stress.

To improve the adhesion between the coating and the base metal, the surface of the workpiece should be dust-free and dry, without rust and grease before coating. In most cases, the workpiece needs to undergo surface treatment. Methods of treatment include sandblasting, chemical treatment, and other mechanical methods. Among them, sandblasting has better effects as it roughens the surface of the workpiece, increasing the surface area and forming hooks, thus improving adhesion. After sandblasting, the workpiece surface should be blown with clean compressed air to remove dust, and the plastic should be coated within 6 hours, otherwise, the surface will oxidize, affecting the adhesion of the coating.

Advantage

Direct coating with powdered plastic has the following advantages:

- It can be used with resins that are only available in powder form.

- A thick coating can be obtained in one application.

- Products with complex shapes or sharp edges can be coated well.

- Most powdered plastics have excellent storage stability.

- No solvents are required, making the material preparation process simple. However, there are also some drawbacks or limitations to powder coating. For example, if the workpiece needs to be preheated, its size will be limited. Because the coating process takes time, for large-sized workpieces, while spraying is not yet finished, some areas have already cooled below the required temperature. During the plastic powder coating process, powder loss can be as high as 60%, so it must be collected and reused to meet economic requirements.

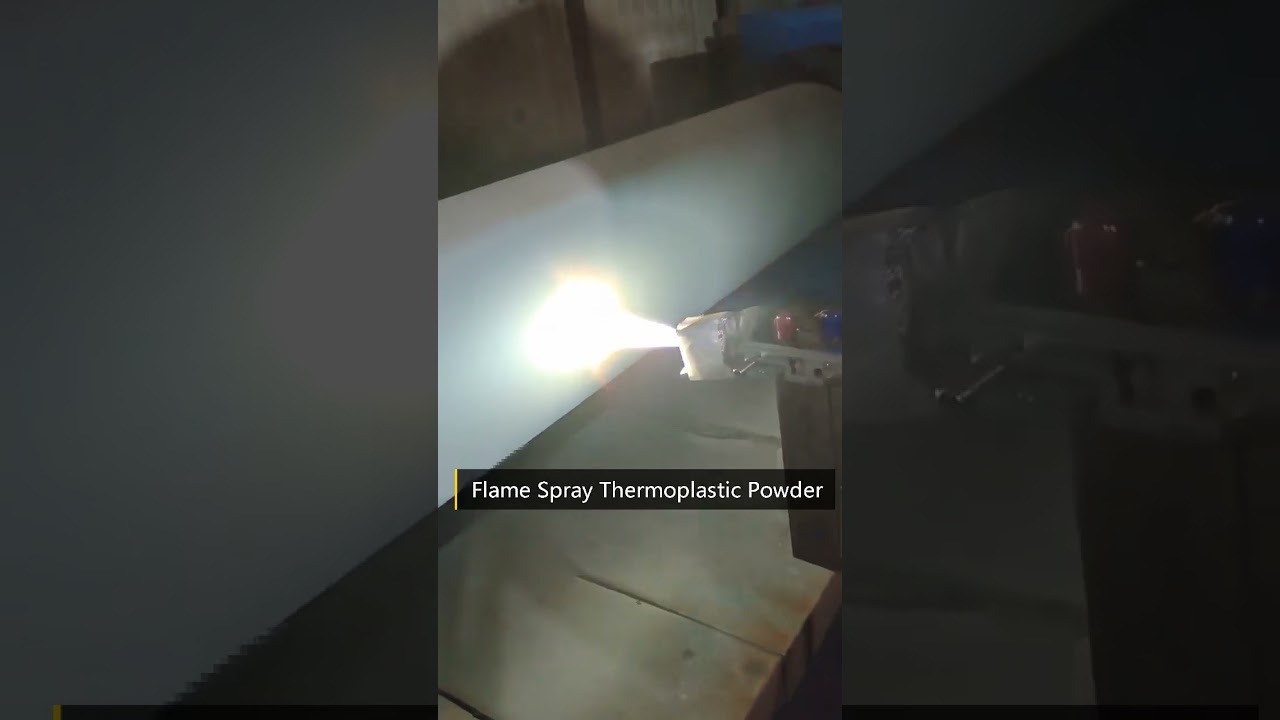

Flame Spraying

Flame spraying plastic coating for metal is a process that involves melting or partially melting powdered or pasty plastic with a flame emitted from a spray gun, and then spraying the molten plastic onto the surface of an object to form a plastic coating. The thickness of the coating is usually between 0.1 and 0.7 mm. When using powdered plastic for flame spraying, the workpiece should be preheated. Preheating can be done in an oven, and the preheating temperature varies depending on the type of plastic being sprayed.

The flame temperature during spraying must be strictly controlled, as too high a temperature can burn or damage the plastic, while too low a temperature can affect adhesion. Generally, the temperature is highest when spraying the first layer of plastic, which can improve adhesion between the metal and plastic. As subsequent layers are sprayed, the temperature can be slightly lowered. The distance between the spray gun and the workpiece should be between 100 and 200 cm. For flat workpieces, the workpiece should be placed horizontally and the spray gun should be moved back and forth; for cylindrical or internal bore workpieces, they should be mounted on a lathe for rotational spraying. The linear speed of the rotating workpiece should be between 20 and 60 m/min. After the required thickness of the coating has been achieved, spraying should be stopped and the workpiece should continue to rotate until the molten plastic solidifies, and then it should be rapidly cooled.

Although flame spraying has a relatively low production efficiency and involves the use of irritating gases, it is still an important processing method in industry due to its low equipment investment and effectiveness in coating the interiors of tanks, containers, and large workpieces compared to other methods.

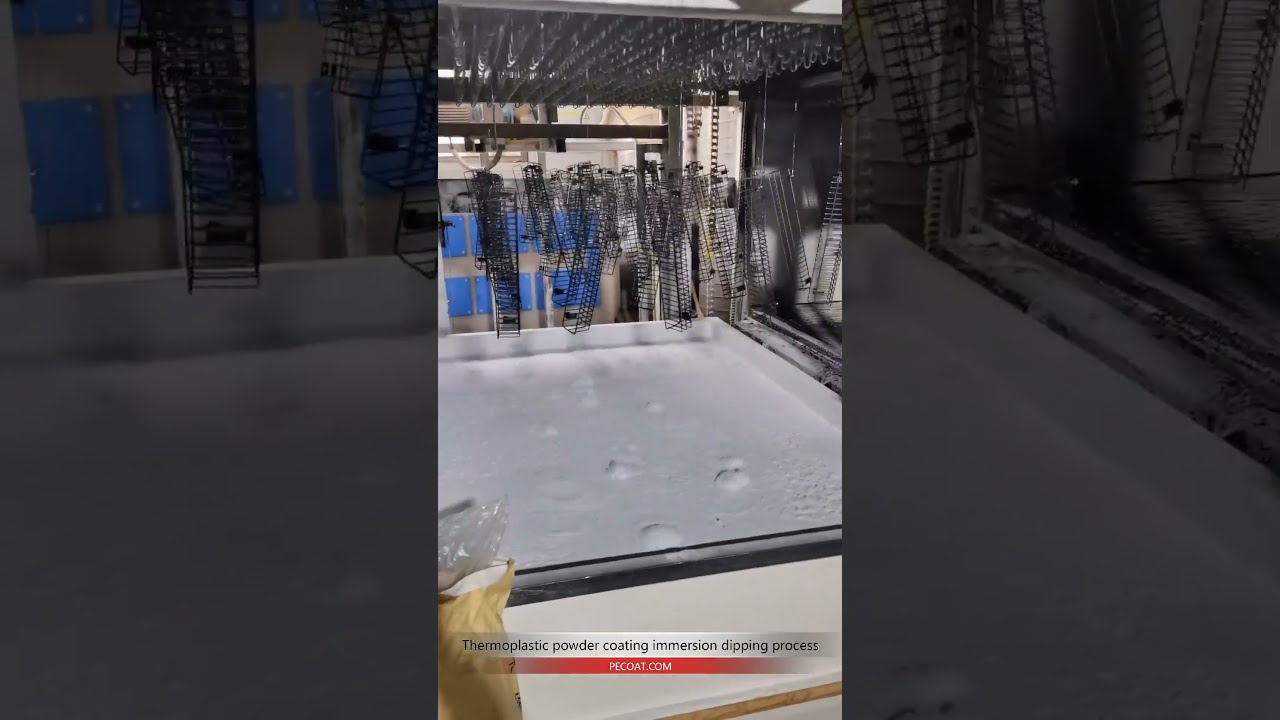

Fluidized-bed Dip Plastic Coating

The working principle of fluidized bed dip plastic coating for metal is as follows: plastic coating powder is placed in a cylindrical container with a porous partition at the top that allows only air to pass through, not the powder. When compressed air enters from the bottom of the container, it blows the powder up and suspends it in the container. If a preheated workpiece is immersed in it, the resin powder will melt and adhere to the workpiece, forming a coating.

The thickness of the coating obtained in fluidized bed depends on the temperature, specific heat capacity, surface coefficient, spray time, and type of plastic used when the workpiece enters the fluidized chamber. However, only the temperature and spray time of the workpiece can be controlled in the process, and they need to be determined by experiments in production.

During dipping, it is required that the plastic powder flows smoothly and evenly, without agglomeration, vortex flow, or excessive dispersion of plastic particles. Corresponding measures should be taken to meet these requirements. Adding a stirring device can reduce agglomeration and vortex flow, while adding a small amount of talcum powder to the plastic powder is beneficial for fluidization, but it may affect the quality of the coating. To prevent the dispersion of plastic particles, the airflow rate and uniformity of plastic powder particles should be strictly controlled. However, some dispersion is inevitable, so a recovery device should be installed in the upper part of the fluidized bed.

The advantages of fluidized bed dip plastic coating are the ability to coat complex-shaped workpieces, high coating quality, obtaining a thicker coating in one application, minimal resin loss, and a clean working environment. The disadvantage is the difficulty of processing large workpieces.

Electrostatic spraying plastic coating for metal

In electrostatic spraying, resin plastic coating powder is fixed to the surface of the workpiece by electrostatic force, rather than by melting or sintering. The principle is to use the electrostatic field formed by a high-voltage electrostatic generator to charge the resin powder sprayed from the spray gun with static electricity, and the grounded workpiece becomes the high-voltage positive electrode. As a result, a layer of uniform plastic powder quickly deposits on the surface of the workpiece. Before the charge dissipates, the powder layer adheres firmly. After heating and cooling, a uniform plastic coating can be obtained.

Powder electrostatic spraying was developed in the mid-1960s and is easy to automate. If the coating does not need to be thick, electrostatic spraying does not require preheating of the workpiece, so it can be used for heat-sensitive materials or workpieces that are not suitable for heating. It also does not require a large storage container, which is essential in fluidized bed spraying. The powder that bypasses the workpiece is attracted to the back of the workpiece, so the amount of overspray is much less than in other spraying methods, and the entire workpiece can be coated by spraying on one side. However, large workpieces still need to be sprayed from both sides.

Workpieces with different cross-sections can pose difficulties for subsequent heating. If the difference in cross-section is too large, the thicker part of the coating may not reach the melting temperature, while the thinner part may have already melted or degraded. In this case, the thermal stability of the resin is important.

Components with neat internal corners and deep holes are not easily covered by electrostatic spraying because these areas have electrostatic shielding and repel the powder, hindering the coating from entering the corners or holes unless the spray gun can be inserted into them. In addition, electrostatic spraying requires finer particles because larger particles are more likely to detach from the workpiece, and particles finer than 150 mesh are more effective in electrostatic action.

Hot melt coating method

The working principle of the hot melt coating method is to spray plastic coating powder onto a preheated workpiece using a spray gun. The plastic melts by utilizing the heat of the workpiece, and after cooling, a plastic coating can be applied to the workpiece. If necessary, post-heating treatment is also required.

The key to controlling the hot melt coating process is the preheating temperature of the workpiece. When the preheating temperature is too high, it can cause severe oxidation of the metal surface, reduce the adhesion of the coating, and may even cause resin decomposition and foaming or discoloration of the coating. When the preheating temperature is too low, the resin has poor flowability, making it difficult to obtain a uniform coating. Often, a single spray application of the hot melt coating method cannot achieve the desired thickness, so multiple spray applications are required. After each spray application, heating treatment is necessary to completely melt and brighten the coating before applying the second layer. This not only ensures a uniform and smooth coating but also significantly improves the mechanical strength. The recommended heating treatment temperature for high-density polyethylene is around 170°C, and for chlorinated polyether, it is around 200°C, with a recommended time of 1 hour.

The hot melt coating method produces high-quality, aesthetically pleasing, strongly bonded coatings with minimal resin loss. It is easy to control, has a minimal odor, and the spray gun used does.

Other methods available for plastic coating for metal

1. Spraying: Fill the suspension into the spray gun reservoir and use compressed air with a gauge pressure not exceeding 0.1 MPa to evenly spray the coating onto the surface of the workpiece. To minimize suspension loss, the air pressure should be kept as low as possible. The distance between the workpiece and the nozzle should be maintained at 10-20 cm, and the spraying surface should be kept perpendicular to the direction of the material flow.

2. Immersion: Immerse the workpiece in the suspension for a few seconds, then remove it. At this point, a layer of suspension will adhere to the surface of the workpiece, and the excess liquid can flow down naturally. This method is suitable for small-sized workpieces that require complete coating on the external surface.

3. Brushing: Brushing involves using a paintbrush or a brush to apply the suspension onto the surface of the workpiece, creating a coating. Brushing is suitable for general localized coating or single-sided coating on narrow surfaces. However, it is rarely used due to the resulting less smooth and even surface after the coating is dried, and the limitation on the thickness of each coating layer.

4. Pouring: Pour the suspension into a rotating hollow workpiece, ensuring that the inner surface is completely covered by the suspension. Then, pour out the excess liquid to form a coating. This method is suitable for coating small reactors, pipelines, elbows, valves, pump casings, tees, and other similar workpieces.

i am looking for thermoplastic coatings for metal wire

This internet site is my breathing in, really good layout and perfect content .