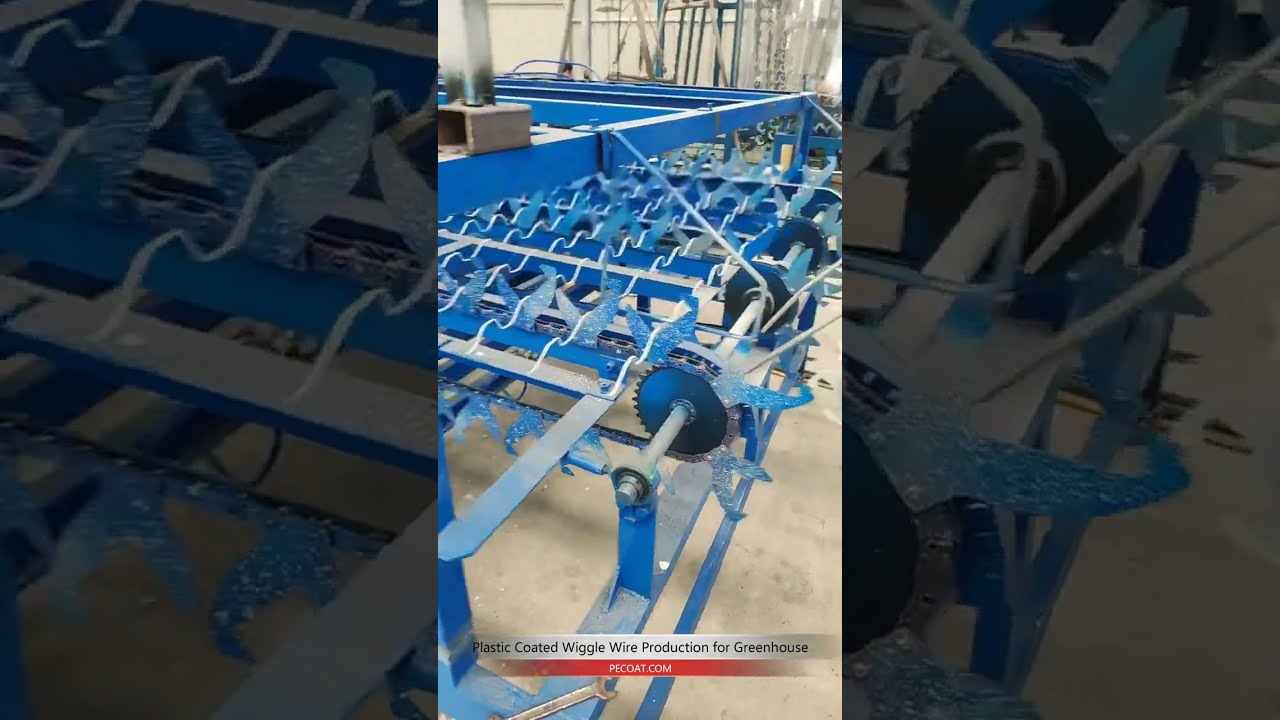

PE Plastic Powder Coating For Wiggle Wire Spring Wire-Lock

Polyethylene Powder Coating for Wiggle Wire for Greenhouse

PE Plastic powder coating for wiggle wire is a process that involves applying a layer of plastic powder( usually polyethylene PE powder) onto a wiggle wire to provide protection against corrosion and wear. The process is commonly used in the agricultural industry for greenhouse construction, as wiggle wire is a key component in securing greenhouse film to the structure.

The first step in the PE plastic powder coating process is to prepare the wiggle wire for coating. This involves cleaning the wire to remove any dirt, grease, or other contaminants that may interfere with the adhesion of the coating. The wire is then preheated to a specific temperature to ensure that the coating will adhere properly.

Once the wiggle wire is prepared, it is coated with a layer of PE plastic powder using an electrostatic spray gun or fluidized bed flock dipping process. This creates a uniform coating that adheres tightly to the wire.

After the wiggle wire is coated, it is cured in an oven at a specific temperature for a set amount of time. This allows the plastic powder to melt and flow, creating a smooth, durable finish. The curing process also ensures that the coating is fully bonded to the wire, providing maximum protection against corrosion and wear.

There are several benefits to using PE plastic powder coating for wiggle wire. First, the coating provides excellent protection against corrosion and wear, which extends the life of the wire and reduces the need for frequent replacement. Second, the coating is available in a wide range of colors, allowing for customization to match the color scheme of the greenhouse. Finally, the coating is environmentally friendly, as it does not contain any solvents or volatile organic compounds.

In conclusion, PE plastic powder coating for wiggle wire is a highly effective process for protecting wiggle wire from corrosion and wear. The process involves cleaning and preheating the wire, applying a layer of plastic powder using an electrostatic spray gun, and curing the coating in an oven. The resulting coating provides excellent protection and is available in a wide range of colors.

I need this production line machine,do you supply?